Abo ut

Peak Resource Planner (now a part of Peak Test Management Suite) ensures a better utilization of test facilities

Peak Solution was commissioned by a worldwide leading manufacturer of gas engines with the design and implementation of software tools to support development and test processes. Important fields of application for the gas engines of the company are modern gen sets in container design and cogeneration units for power supply.

The aim of the project was to considerably reduce the heavily increased costs for manually planning and implementing the wide range of development and test activities. This should be achieved through the introduction of a universal, component-based software solution.

By means of the requests and requirements from the department, Peak Solution first designed a suitable system topography which sensibly bundled the functional requirements of users along the process chain into individual software components. During the design of the system topography, the process know-how and the many years of practical experience gathered by Peak Solution from comparable projects in the automobile sector came in extremely useful.

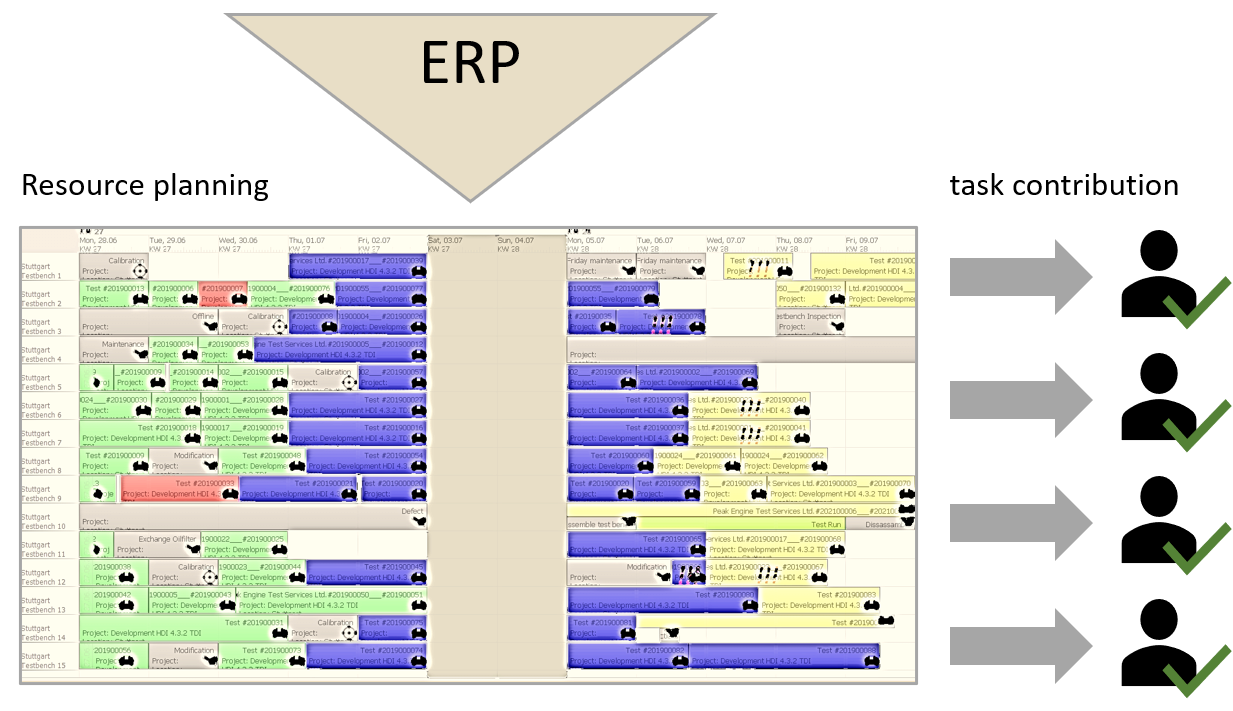

In a further stage, those software components that were to be implemented first were identified and prioritized, based on the system design. This mainly involved the planning of resources and capacities, as well as the scheduling of tests. With the Peak Resource Planner, Peak Solution was able to provide a powerful basis solution which was quickly and flexibly adapted, through customizing, to the specialist tasks and requirements of the customer. The following core functionalities were first implemented in the Peak Resource Planner (PRP):

- Test definition and development

- Scheduling of tests

- Managing and scheduling the required resources

- Testing the capacity of the resources used

- Creating the jobs for the departments

Since the customer manages a large part of the resources required to perform the tests in a central ERP system, a connection of the new solution to the central ERP system was planned. Certain types of occupation of resources that are maintained centrally outside the development and test departments (e.g. calibration, maintenance, etc.) can in this way be taken into account promptly during the capacity testing.

Through the generic approach of the Peak Resource Planner, it is ensured that new technical requirements can also be mapped quickly and flexibly in future, without programming expenditure.