Abo ut

Peak Solution standardizes the evaluation of operational data for test benches

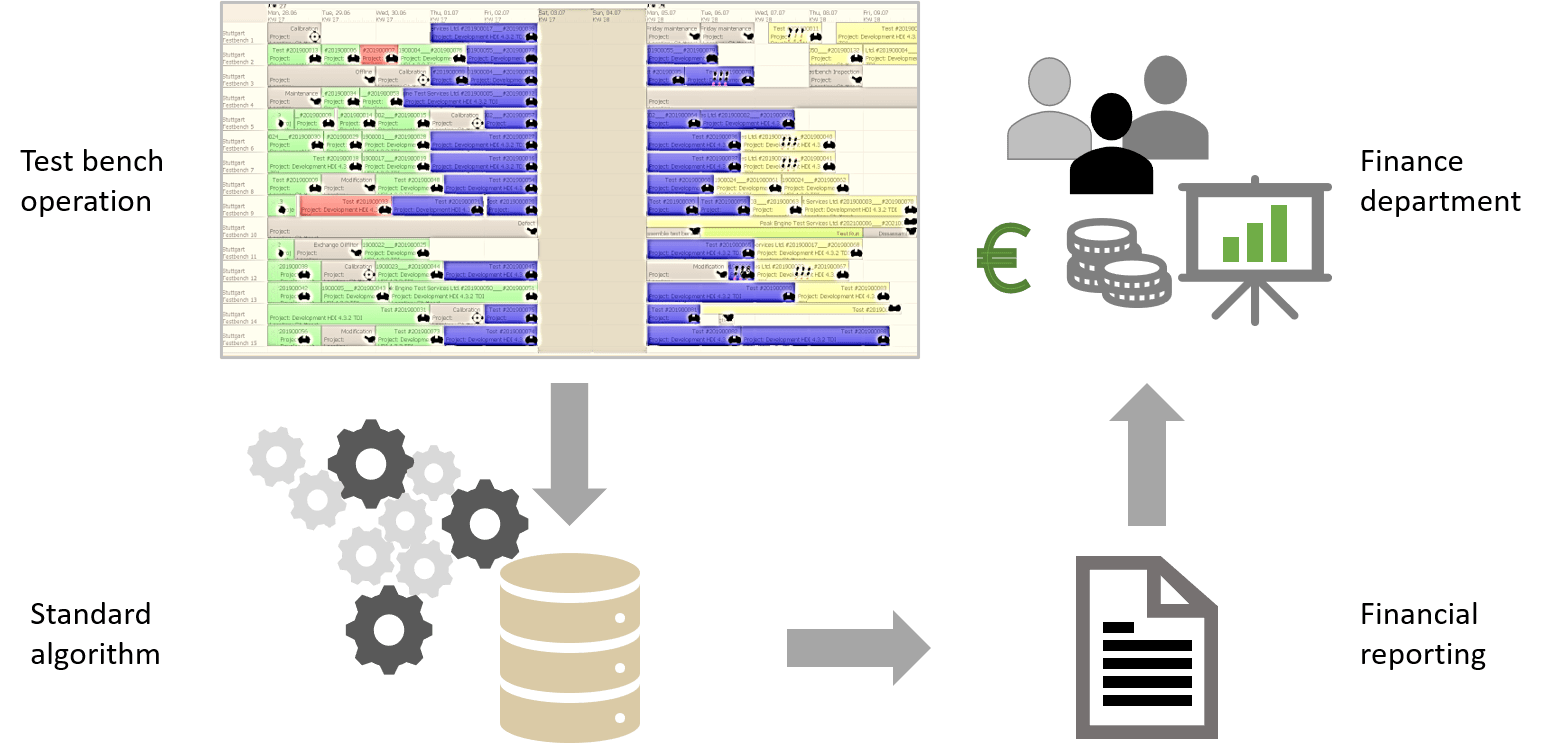

In the facilities of a large German automotive manufacturer, the scheduling of vehicles on roller test benches is implemented by an individually designed planning application. The system was developed in 2006 by Peak Solution GmbH and has since been successfully deployed in production scenarios.

Test bench operators are the users of the planning application. In the process, they serve as internal service providers for the design engineers. Design engineers define the tests, which are then substantiated, scheduled and performed by the test bench operators. The test results are subsequently made available to clients.

A wide range of operational data is generated on the test bench as the test is conducted. This involves, for instance, information about the allocation types or allocation times for the test benches and, if required, the consumption of process materials. This operational data is used, among other things, for billing purposes.

Peak Solution was commissioned to design and implement a tool which would consistently support the evaluation of operational data from different factories and test bench groups. It was intended to replace the MS ACCESS and MS EXCEL solutions used until then in the individual branches.

An application was created that today offers the possibility of storing operational data for any configurable amount and type of test benches centrally in a data warehouse and generating monthly and yearly evaluations on usage and downtimes, as well as providing cost center accounting.

The application can be expanded without problem at any time through the use of a report generator. Sending the evaluation report to those responsible is done from the application via email.

Additional test benches and test bench groups can be integrated into the system without problem at any time via a defined interface.