Abo ut

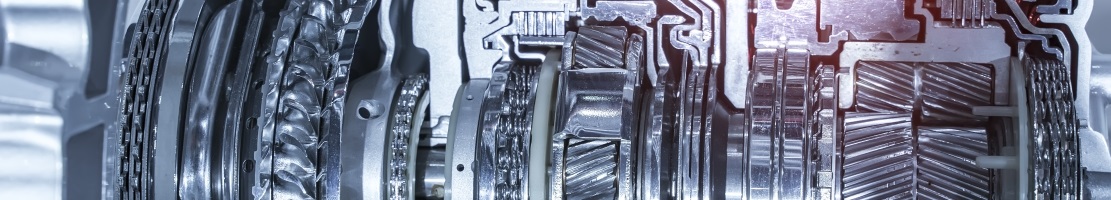

Chinese car manufacturer has established an efficient test process in the transmission department

Our customer is a large manufacturer of SUVs and pick-up trucks in China. The company develops all the essential components of its vehicles by itself. For this purpose, 18 test bench systems from different manufacturers are in use in the transmission department.

In order to optimize the utilization of these cost-intensive test resources and to improve the adherence to schedules of the test department, the company decided to implement an efficient, comprehensible and flexible test process. One of the core tasks was to avoid assignment conflicts with test stands, measuring instruments, test parts and other test resources. In addition, the managers wanted to ensure the systematically storage of all the test results for a long-term interpretability.

Based on the Peak Resource Planner, our customer has set up a multi-level test process. For a planning period of approximately 3 to 5 years, the head of a development project first defines and schedules all necessary test series. Starting from this “Design Verification Plan (DVP)”, the respective test engineers then gradually refine the test series. This include, for example, the specification of the individual tests within a test series, the planning of the test sequence and the determination of the test resources required for the tests. Predefined templates in the Peak Resource Planner ensure that the description of the different tests is based on uniform structures. The software also controls the process for the approval and commissioning of the tests.

The test field operators finally carry out the detailed planning of the test orders. Peak Resource Planner (now a part of Peakt Test Management Suite) informs about the availability of the required test resources and supports comfortable planning functions for their conflict-free allocation.

During the execution of the tests, the application informs all actors by means of notification mechanisms on defined events. After a test has been completed, the measured data obtained are linked with the corresponding test order. Powerful search functions ensure that users can retrieve the data quickly at any time. In this way, all tests are documented comprehensible in the long term.

All information that is generated during the test planning and execution (for example, productive times, running and failure times of test resources, throughput times of test orders, etc.) are evaluated by the management for process optimization.

Overall, the trasmission department is now benefiting from very clearly defined and comprehensible processes in the test environment.